Capabilities

20 years ago, MingFeng started as a small crafting workshop. Now it has become one of the leaders in the packaging industry with the most advanced technologies that enable mass packaging production for a variety of products.

Cost Effective Packaging Solution

The variety of paper and leatherette for the exterior provide great flexibility to the packaging design. There are so many different colors, patterns and finish for you to choose from. In addition to the variety of choices, special printing techniques such as foil stamping and UV-coating can be applied on the surface of the paper and leatherette, providing you even more options on the visual design.

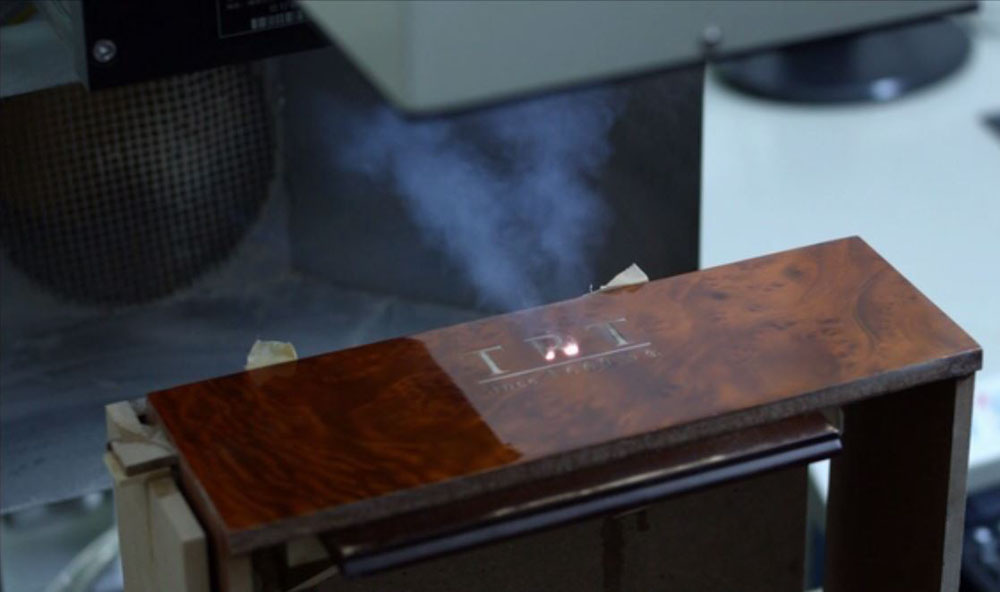

Natural and Elegant

Compared to paper boxes, wood boxes are much heavier. The weight gives the boxes an elegant and natural touch which no other boxes can match. With the special techniques such as lacquering and laser engraving that are only applicable onto wood boxes, a designer can add so many different color patterns and visual effects onto the boxes. If you just like the natural look of wood, then you can use glossy transparent paint to retain the natural wood pattern.

A Combination of Sturdiness, Light Weight and Durability

The advantage of plastic boxes is that they are not as sensitive to humidity and temperature as the paper boxes and wood boxes, making them a great packaging solution for those who seek high durability packaging. plastic boxes are also great for transportation because they are sturdy and light.

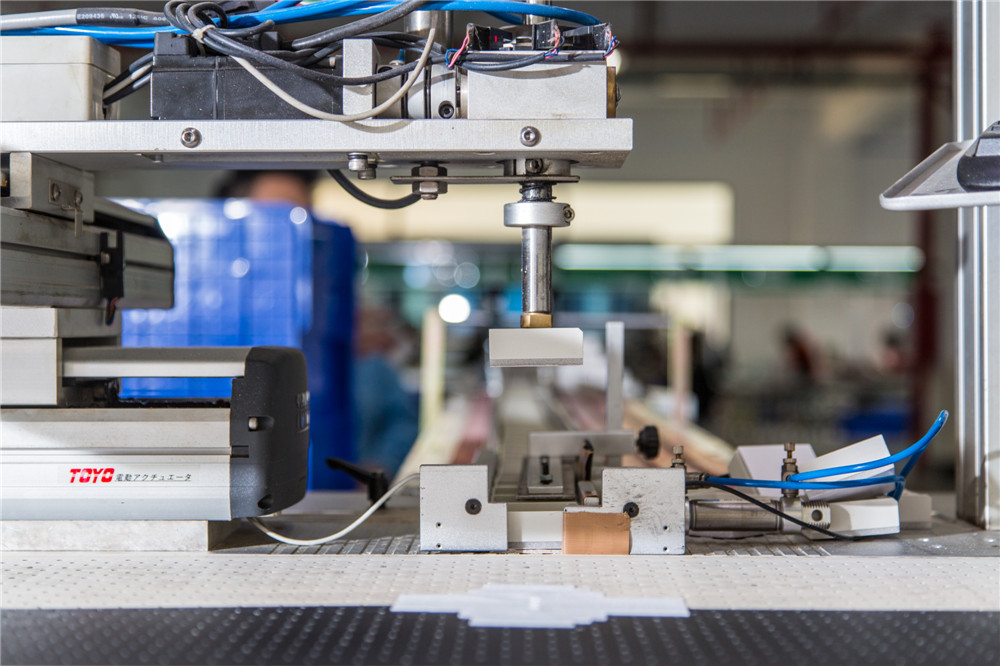

Accuracy and Flexibility

One of the greatest benefits of laser engraving, is that the speed of the guns movement and the power of the beams, can be controlled. A combination of gun movement speed and beam power can help carve very complicated graphical designs. Also, the laser beam is very thin, which creates great accuracy comparing it to traditional cutting and engraving machineries.

Water and Scratch Proof

Laminating is a technique to cover a printing product with a transparent plastic film. The plastic film is so thin that you cannot visually distinguish whether a printing product has been laminated or not by the thickness. The plastic film adds shiny or matte effects on the surface of a printing product and can protect it from erosion, scratches and water.

Laminating methods include:

- Matte Film

- Bright Film

- Laminating and Foil Stamping

- Laminating and UV-inks

UV-ink Popularity

Coating and glazing techniques put on transparent inks on the surface of a printing product, highly increase the quality of the finish and the shininess of the product surface. This technique is usually used to emphasize a section of the graphic design. Transparent UV-ink is often used as the coating materials in the production process.

Traditional Paper Cutting Technique

Die cutting is the process of using a metal die to cut low-strength materials, such as sheet metal, paperboard, foam and plastics. Dies are usually equipped on a rotary which make the production much faster than on a flatbed.

Die cutting is a traditional way of cutting or engraving materials in desired shapes. Even though it might not be able to create intricate artworks like the laser machines due to the limitation of the metal dies, it is still widely used in the industry due to the ease of use and low cost.

Stamp a Shiny Metallic Logo

Foil stamping is a technique to stamp a shiny metallic design on paper. A foil stamping machine consists of a metal die, a metallic leaf and a flat surface where you put the substrate materials on. The idea of foil stamping is to apply pressure and heat on the metallic leaf from the metal die, which pushes the metal leaf onto the substrate materials, thus leaving the desired shape.

Add Dimensional Finish on Paper

Embossing is the process of creating a raised relief shape or design on paper. It is usually done by applying pressure and heat from two dies – one is raised and the other is recessed. Embossing is usually used in combination with foil stamping to create a three-dimensional metal effect on a paper surface.